By Pepper Parr

BURLINGTON, ON July 18, 2011 — They have a secret recipe and are using it to rid the seas of the world of some very significant pollution. They have sales that exceed $20 million, 100 plus people on staff at a plant on Mainway and no one in Burlington buys anything from them. They were recently nominated for a coveted Ocean Environmental Protection Award.

BURLINGTON, ON July 18, 2011 — They have a secret recipe and are using it to rid the seas of the world of some very significant pollution. They have sales that exceed $20 million, 100 plus people on staff at a plant on Mainway and no one in Burlington buys anything from them. They were recently nominated for a coveted Ocean Environmental Protection Award.

Don’t look for a sales counter at Thordon Bearings – they don’t have one. But they do have distributors in more than 73 countries and have sold their product to more than forty different navies and are in the process of prototyping a product that they believe will replace the use of some bronze in the marine line of bearings

The basic premise behind everything the company does is the replacement of metallic bearings with the polymers they first developed in 1969 and have been improving upon ever since.

Thordon Bearings designs and manufactures a complete range of high performance, non-metallic journal bearing solutions for marine, pump, hydro-turbine, offshore oil and other industrial markets. From water lubricated stern tube and rudder bearings for ships to grease free wicket gate bearings for clean power generation, they provide innovative non polluting bearing solutions that meet or exceed the technical requirements.

The Thomson Gordon business focuses on the propeller of a ship and in this image the propeller has been removed.

The company has more than 10% of it’s labour force doing research and development and includes three people with doctorates in their field. This is very much a company that is breaking new ground in product development – all based on a secret recipe that is used in their manufacturing process that takes place behind screens that prevent visitors from even seeing what they do and how they do it. But they do it rather well and the growth potential for the company is close to unlimited.

The only account they haven’t managed to crack is the Adam Beck power generation plant at Niagara Falls “We do have our product in power generation plants in Northern Ontario” added Carter and we do a lot of business with Hydro Quebec.”, he added.

Mayor Rick Goldring, who is focused on improving and upgrading the make up and mix of companies headquartered in Burlington said: “While we share the disappointment in Thordon Bearings not winning the Ocean Environmental Protection Award, we nevertheless recognize their significance as a leading employer in Burlington that is allocating a significant portion of their 100 plus employees to research and development.” The Mayor added: “Their participation in the Burlington economic scene is both very welcome and satisfying.”

Formed in 1911, the organization is in its fourth generation of leadership with a succession line that will place the leadership on the shoulders of Anna Galoni who is the current vice chair. Founded by Chairman Sandy Thomson’s grandfather, army major George J. Thomson and his brother William, the company was in the business of repackaging and distributing industrial products. They later took on a partner and renamed the company Thomson Gordon when it was incorporated in 1916. The business flourished and by 1936 they were into manufacturing products for industrial engineers.

The son of the founder, Sandy’s father, graduated from Pratt Institute in New York with an architectural degree. He completed his studies during the Great Depression and found work as a commercial photographer. He soon answered his father’s summons to help run the business in Canada, which he did for the next 30 years. That put the second generation in place and the evolution continued in 1967, when Sandy took the reins of the company from his father, George J.V. Thomson.

Sandy Thomson had decided he didn’t want to be in the family business and chose to study aeronautical engineering at Northrop University in California. “I wanted to be an aerospace engineer,” George “Sandy” Thomson said, remembering his college days during the 1960s at Northrop University in Inglewood, California. “My mentor was a senior engineer who was absolutely brilliant, and we played in a band together. I really thought I had found my place in life because I didn’t want to be involved in the family business. However, the dean of the school talked me into going from aerospace to mechanical engineering because he said there would be many more opportunities, so that’s what I did. In fact, I did my final mechanical project design on seals for pumps.” That work with pump seals took Sandy into a career that has revolutionized the way propeller shafts are lubricated around the world.

The firm had a broad selection of product offerings and expanded often, but in a little corner of the plant Sandy was working on his non-metallic bearings concept. Sandy and production foreman Arnold Lange were coming up with a number of ingenious uses for newly discovered polymers and soon began solving bearings problems with an entirely new type of bearing system.

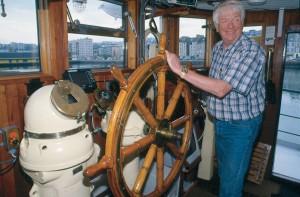

The only way Sandy Thomson felt he could convince ship operators to use his product was to have a ship using them – so he bought a Russian steam operated tug boat and outfitted it with his product and then sallied from port to port – 200 in all to show what kind of a difference his products could make. Many Thordon Bearing staff members can remember tours on duty on the Rudokop which was later sold to Norwegian interests. It was a Sandy Thomson original trade show.

Having a great product is one part of a great business operation – selling it is the other part and Sandy, in his typical innovative fashion took his product to the market using a ship he had purchased, a Russian deep sea salvage steam tug, the Rudokop, and converted it into a floating showcase for the company’s marine bearings and seals. Over a 14-year period, the tug visited more than 200 international ports. It was crewed by six Eastern Europeans and captained by Thomson himself. Burlington staff would take turns being part of the crew to explain the product line. As a traveling road show the tug and its crew was a great success in introducing ship owners to Thomson’s radically new approach to lubricating the shaft of a ship’s propeller with sea water instead of oil.

“My grandfather didn’t do very much with bearings in his day. He did look at synthetic polymers but felt the science was too complex for him. He actually thought it was too complicated for Sandy as well, but the young Thomson envisioned three products that could be made from polymers. One was a flexible machinery mount. Another was a flexible coupling for a shaft, and the third was a rubber bearing for pumps. “So I came up with the idea of using an elastomer blend to work as a pump bearing and our first customer was a Canadian steel company,”

“Our bearings worked much better than the rubber bearing in vertical scale pit pumps, which were pumping scale water out of the pits. Then it hit me: Why not use my new bearings on propeller shafts for ships? While the company didn’t enter into the maritime markets for a few more years, I knew we had a winner.”

At the time the company did not have a testing facility for the new polymer bearings. So a few years before entering the maritime market, Thomson worked with a couple of senior engineers at Stelco to test the new product: “These engineers bought our polymer bearings and put them into places even I thought they didn’t have a chance to work, and they didn’t, but the cost was covered in the plant’s maintenance budgets. We did a lot of testing and I give those engineers a lot of credit for helping us in our early days.”

The Canadian Navy Halifax class frigates gave Thordon Bearings their entry into the marine business. With their products on ships of this class and level the rest of the marine world had to pay attention and look seriously at the products. They did and the company grew.

When Thordon Bearings entered the maritime market, its biggest client and supporter was the Canadian Coast Guard. While a couple of tugboats used the propeller shaft bearing, the company knew they really had to be proven on the next level of ships. “The Coast Guard came along and gave us a chance,” reminisces Thomson. “I don’t want to say it was easy, because it wasn’t.

Products go through different departments as the come from manufacturing to finishing and into shipping where they are sent to more than 70 countries around the world. China is the companies biggest customer.

In the days when Thordon first began business, 95 percent of the ships in the world had propeller shaft bearings of white metal with stern tubes of oil for lubrication. At the time the systems were state-of-the-art and no one worried much about a seal leaking. In fact, marine vessels had very little environmental compliance issues to deal with. When Thordon decided to eliminate oil and replace propeller shaft lubrication with seawater, many thought the concept was going backwards. Thomson reminds us that shaft bearings were made of wood until the 1950s. More importantly, wooden bearings would only last for about five years. So companies began manufacturing white metal bearings and using oil as a lubricant to extend the life of the bearings.

Thordon Bearings has a lock on the market for propellers and rudder bearings on those specialized vessels that push barges up and down the Mississippi River where the mud and particles in the water get cleaned out of the propeller shafts that are lubricated by the river water.

While attitudes change slowly, today’s environmental push has never been more comprehensive, and losing a few liters of oil a day from a leaking seal is no longer acceptable. Thomson points out that in 1998 Thordon installed a seawater propeller shaft bearing on Carnival Cruise Lines’ Grand Princess. Thirteen years later, during an extensive refit the strut and stern tube bearings were checked and found to be in exceptional shape.

Thomson says the bearings on the Grand Princess could be in great shape for 20 years, which is unheard of. “When we started guaranteeing 15 years of life for our seawater propeller shaft bearings, people thought we were nuts,” he said. “We’re not in the spare parts business, so we manufacture our bearings to last the life of the ship.”

We` are a much more environmentally conscious society and it is no longer acceptable. With bearings that have a 20 year life span a lot of oil is kept out of the water.

The more than 100 employees who manufacture products result in significant savings for their clients and keep a lot of oil out of the sea lanes. Operated as a company that constantly innovates Thordon Bearings uses a team of nine area agents who supervise agent/distributors in 73 countries. Craig Carter, Director of Marketing and Customer Service, explains that by using local distributors we can be both international and at the same time very local. Our distributors have been with us for a very long time and they have their ears to the ground in their markets.

Sandy Thomson is both an engineer and a captain who understands the waters ships sail on and the equipment they need to ensure a safe voyage. He is also fully aware of the increased environmental consciousness that is keeping the sea lanes cleaner than ever before.

However, to be successful around the world, you also need credibility at home. “When our products were specified for the Halifax class patrol boats used by the Canadian Navy we had immediate bona fides with other navies and as a result of that we sell to navies around the world including the United States where the four Nimitz class aircraft carriers use our products.

Today the company has outfitted about 2000 vessels with its oil-free, seawater-lubricated bearing system. Thomson says the company has expanded to Poland and Saint Petersburg, Russia to complement the Canadian facility.

Sandy Thomson is winding down a little today at the company. His new passion is an old one with him, film-making. He is working on documentary films and only spends a couple of days a week at the office. Thomson recently re-released a DVD – “The Eyes of Memory” that he shot in 1972 with a 16 mm camera that he will tell you is the only film format that is going to survive. The 32 minute reflection on Burlington is a joy to watch – give Sandy’s office a call and get a copy. Might even be on at the Library you can borrow.

Succession is critical for any business. Thordon Bearings know today what the fourth level of succession is going to be. Anna Galoni will lead an engineering company in an industry that doesn’t have very many women in it and lead the company deeper into the marine market where woman are rare. Once again Thordon Bearings innovates and leads.

Sandy’s stepdaughter, Anna Galoni, is a Polish-born epidemiologist by training and is now the firm’s Vice Chairman. She will eventually succeed her stepfather. The company is going to celebrate its 100th anniversary in September and Sandy has a large container of old papers and memorabilia to sort through for that event. Then, perhaps another film or two and maybe some ideas for a slightly better polymer bearing. There is also the old lighthouse on the Burlington canal, built before Confederation, that Sandy would like to see renovated. A great, great, grandfather of his was at one time the lighthouse keeper.

Both the company and staff are deeply involved in the community. They were major donours to the building of he Burlington Performance Arts Centre and are involved in the Canadian Warplane Heritage Museum where Sandy and members of the staff provide volunteer hours in restoration projects.

Guys like Sandy Thomson don’t retire – they just keep on going round and round – much like the propellers that his bearings support.

[retweet]

[…] third generation leader, Sandy Thomson and production foreman, Arnold Lange. Since that time Thordon has continued to develop, test and introduce new polymers in a search for new innovative products that solve our […]